Laboratory of Vision Systems

1. Research and measurement opportunities

In the field of technique and medicine we have been developing methods and measurement algorithms based on vision methods which allow one to perform the following tests:

- 3D structure and motion reconstruction

- Vision-based mobile robot control

- Vision-based underwater robot control

- Active vision systems in underwater robot control

- Surface’s damage detection of the underwater concrete tanks

- Vision-based measurements and quality control

- Objects identification and localization

- Digital image processing

- Robots’ repeatability and trajectory investigation

- Rapid prototyping of vision algorithms and visual servoing algorithms

- Medical image processing and analysis

- Vision-based control of medical robots

- Light microscopy images of animal tissue processing and analysis

- Vision-based examination of mechanical properties of biological materials

- Anthropometry and biomechanical analysis of human body motion supported by vision systems

- Vision-based measurement of displacement and deflection of engineering structures

- Vision-based measurement of engineering structures’ vibrations

- Vision-based damage detection

- Modal analysis based on vision signals

- Recording and visualization of mode shapes (in the slow motion mode)

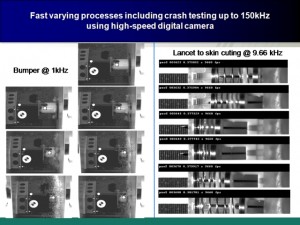

- Fast varying processes recording and analysis (including crash tests)

- Measurement of displacement fields representing in-plane deflection of a construction

- Measurement of 2D/3D deformation of the whole construction or its regions.

- 2D and 3D measurement of vibration courses in selected points of the construction

- Mode shapes visualization carried out by a fast digital camera

- Measurement of vibration courses in the range from 0 do 300 Hz and mode shape visualization in the rage 0 – 20 kHz

2. Instrumentation and laboratory equipment

- Two Phantom v 9.1 high-speed camera (2 Megapixel resolution , up to 150 000 frames/sec) completed with set of lenses and photographic equipments.

- X-Stream XS-3 high-speed camera (1 Megapixel resolution , over 57 000 frames/sec) completed with set of lenses and photographic equipments.

- Industrial cameras and web cameras as a part of vision systems components or integrated with robots ( integrated with industrial and mobile robots).

- Two Canon EOS 5D Mark II SLR cameras (21 Megapixel ) completed with set of lenses and photographic equipments.

- ATOS I 2M 3D scanner for 3D object reconstruction equipped with software to inverse engineering and quality control.

- TEMA AUTOMOTIVE – dedicated software for 2D/3D motion analysis (exemplary application: advanced motion analysis in the automotive industry, in biomechanics, etc.).

- The motion analysis in three-dimensional space consisting of two high-speed cameras and Tema Automotive software (max. recording frequency 150 000 frames/sec).

- The motion analysis in 6D dimensional space consisting of one high-speed camera and Tema Automotive software (max. recording frequency 150 000 frames/sec).

- AdeptSight 2.0 vision system cooperated with Adept Viper s650 Robot.

- In-house vision system for structural health monitoring of structures composed of several Canon digital cameras and wiz2DDeflection software.

- Efficient hardware–software environment MATLAB/Simulink/dSPACE (for real-time simulation and prototyping on dSPACE hardware).

|

|